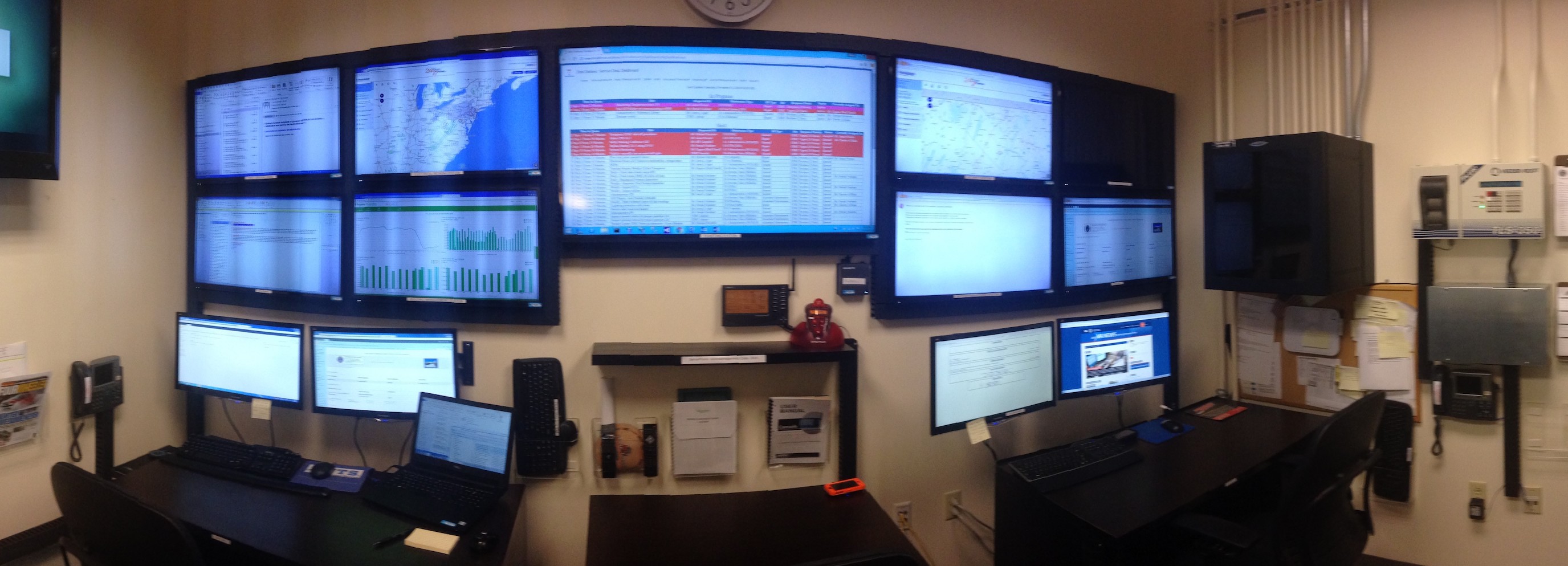

Command Center

WTS | First Defense can help create a command center that will watch resources, maintain safe operating conditions and respond to emergencies. This can improve efficiency and create seamless emergency response. Below is an example of custom-designed command center for a data center. Careful attention to detail was followed to meet the customer’s requirements.

Monitoring & Troubleshooting

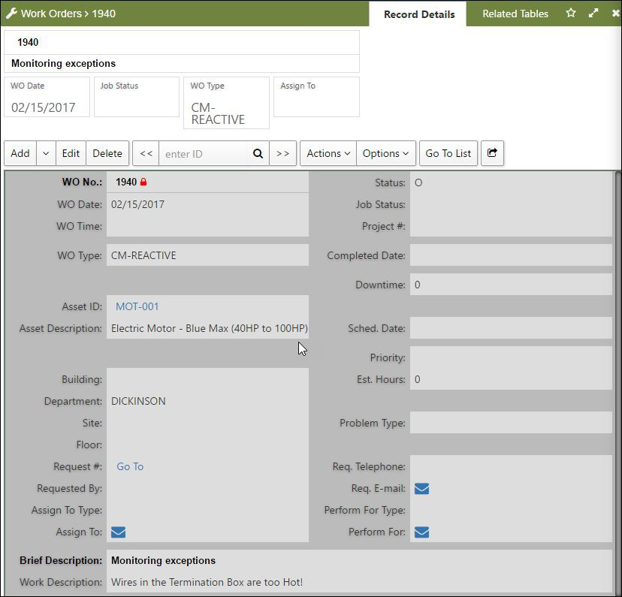

Access to real-time data can proactively advise of potential failures and can dispatch immediately.Using real-time dashboards on system performance, and referencing other resources in order to make effective decisions.

Maintenance Planning

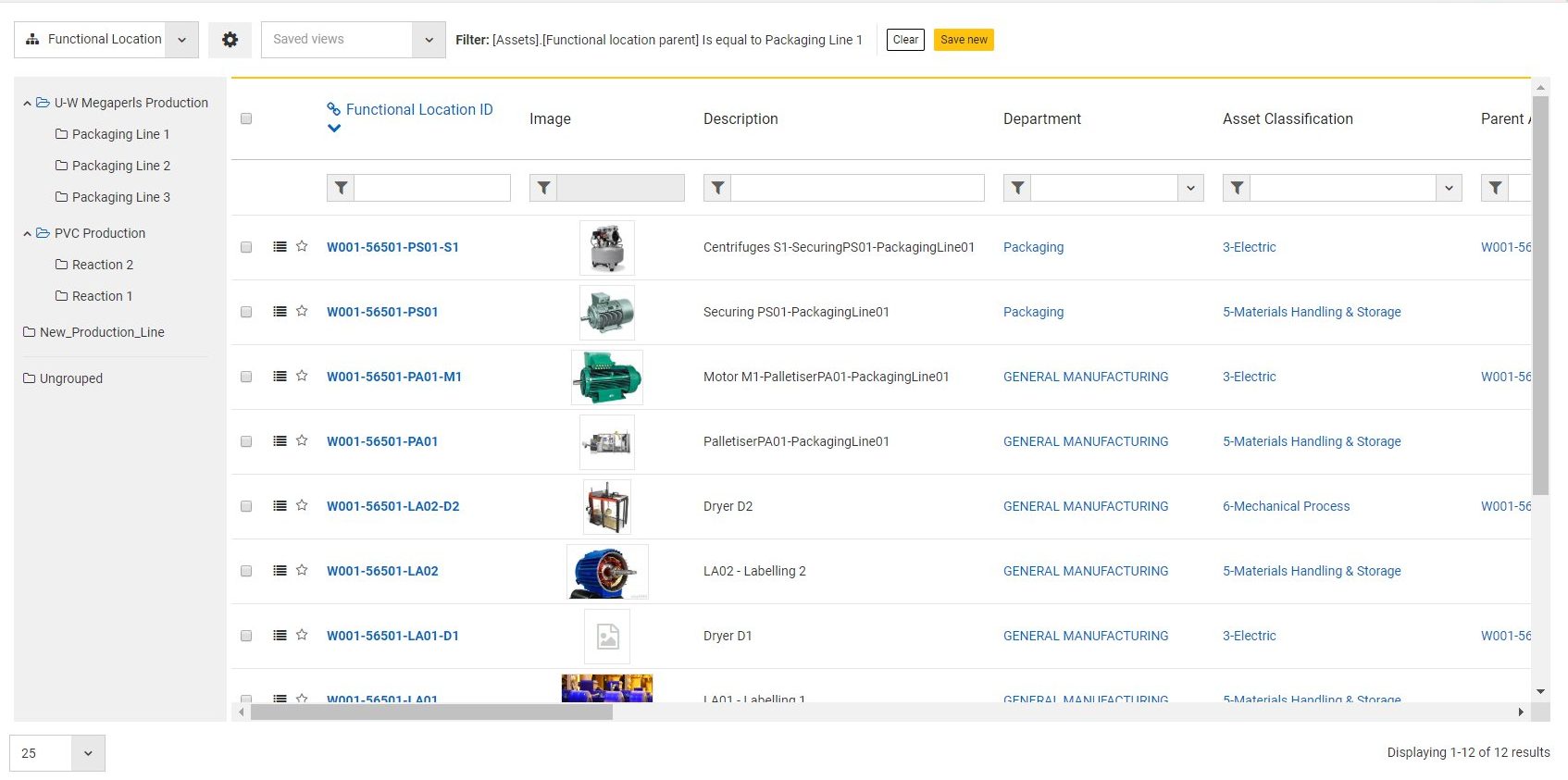

Developing and implementing a program for maintenance, support, and repair helps maintain optimal performance.Maintenance, support, and repair involves developing and carrying out standard operating procedures, specific maintenance requirements, and regular preventative maintenance.

Analyze & Reporting

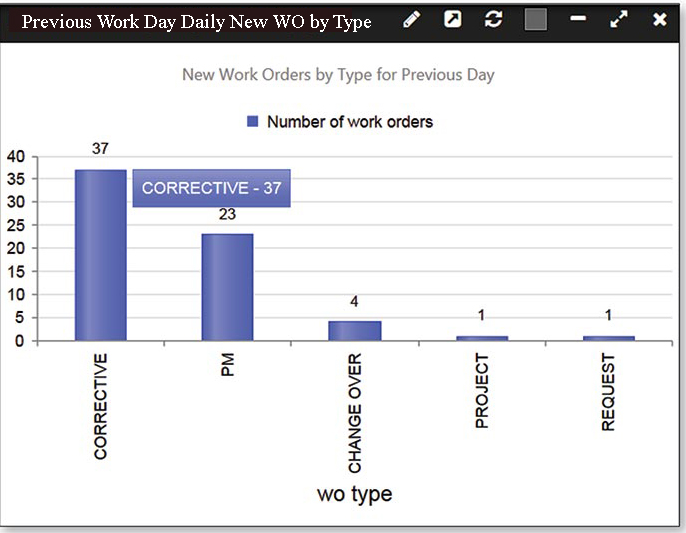

Data-driven analytics can proactively advise of potential failures.Analyzing data fundamentally can improve the ability to service critical equipment prior to failure. Reports can be created to track productivity, material usage and spot key performance trends.

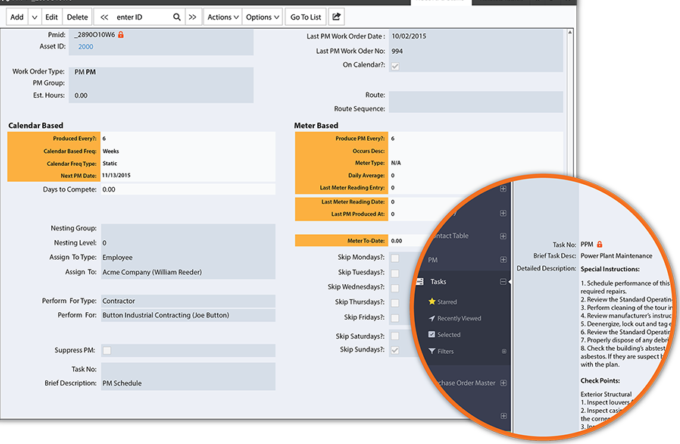

WTS | First Defense uses an automated tracking system to track all customers and contract work. This system is used to plan, schedule, track, maintain, and generate records of all activities related to equipment service.

With work order scheduling software work orders can be assigned to on-site and field technicians.

Dashboards and reports can be created to follow the flow of work being performed. These can be configured into tables and graphs for further analyzing.

Standard operating procedures and specific maintenance requirements are atttached to work orders to ensure process consistency and any compliance requirements.

Effectively managing inventory can increase productivity, decrease downtime, reduce spending on parts and boost production operation.